The Ultimate Guide To Fire Rated Spandrel Panel

Table of ContentsThe smart Trick of Aluminium Spandrel Panel That Nobody is DiscussingThe Ultimate Guide To Gable Spandrel PanelThe Greatest Guide To Curtain Wall Spandrel Panel DetailAll About Aluminum Spandrel PanelThe Facts About Gable Spandrel Panel Uncovered

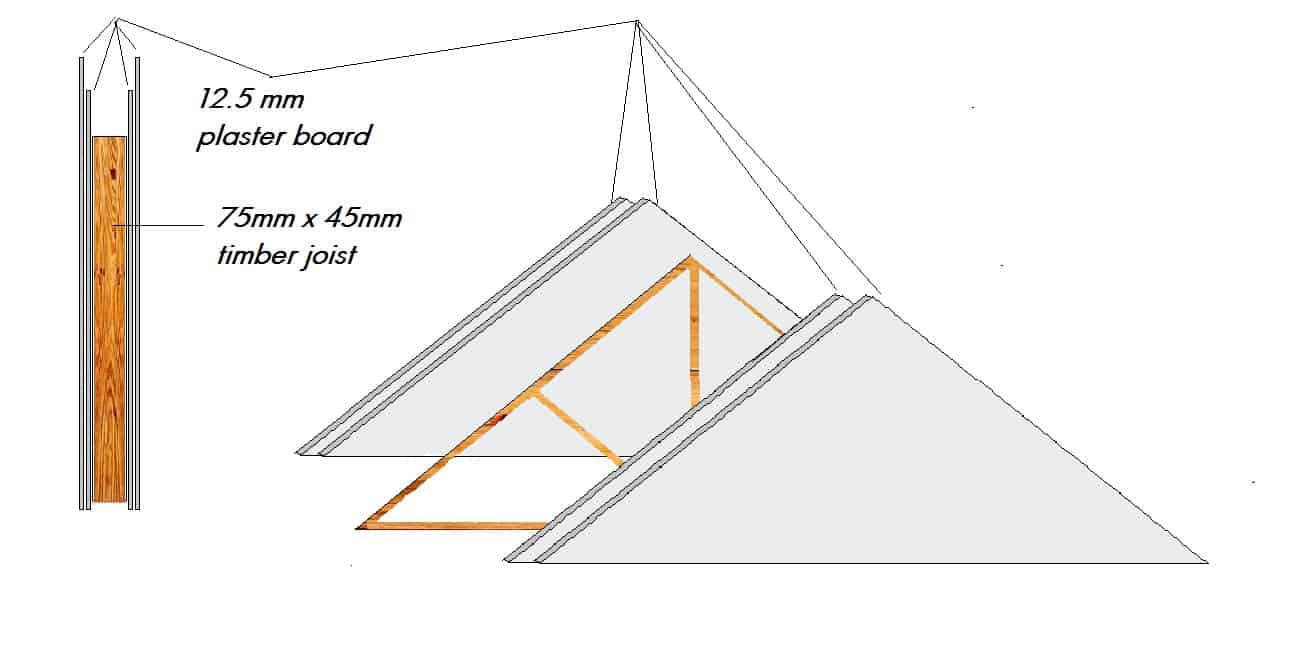

Spandrel glass often is additionally reflective, which helps it to mask the space behind it.Spandrel panels should be designed on a site-by-site basis by an accordingly certified architectural designer. A complete style with architectural estimations should be supplied that consists of the factors provided below. You need to know that a few of this info may not be supplied by the truss roof covering supplier or lumber framework panel maker.

A design approach verifying at which degrees lateral restraints/support is taken as well as details of the type and mendings of restraint A full collection of structural engineer's estimations to take the sustaining reactions and also note where they are related to the main structure A layout declaration from the job engineer mentioning they have gauged the assistance reactions and included them in the design of any type of supporting elements The fire requirements for each job (border and elevation) defined by the designer/ designer to suit the needs of each task to follow Building Regulations Spandrel Panel Construction Considerations In stonework tooth cavity wall construction situations, the following provisions should be used in conformity with the architectural designer's style: Arrangement for restriction of the top of the inner stonework wall surface where it fulfills the spandrel panel must be supplied.

Repairing of the base of the spandrel panel to the masonry. Lateral restriction of the spandrel panel back to the roof structure (consisting of fixing place and type). In both stonework and wood frame building, a minimum 50mm clear cavity in between the spandrel panel as well as the outside masonry fallen leave must be kept.

Aluminium Spandrel Panel Can Be Fun For Everyone

by a tooth cavity tray. Finally, any cavity trays ought to be splashed by the rest membrane layer to a minimum of 100mm. The wall connection spacing must be taken care of with to the upright studs of the panel (not the sheathing panels) at centres specified in the structural engineer's design Suitable lumber frame wall ties must be made use of to connect the outside skin of masonry to the spandrel panel A rest membrane layer should constantly be integrated on the cavity side of the spandrel panel A drained pipes as well as aerated dental caries needs to be maintained with a minimum 50mm clear dental caries between the spandrel panel as well as the exterior masonry fallen leave A condensation danger evaluation need to be given where fire resistance requirements or internal panel lining mean that the roofing insulation can not be proceeded into the panel Please Note: Every care was taken to ensure the details in this write-up was proper at the time of publication.

Nonetheless, for the most up to date LABC Service warranty technological advice please describe your Threat Administration Land surveyor and the most up to date version of the.

Rumored Buzz on Aluminum Spandrel

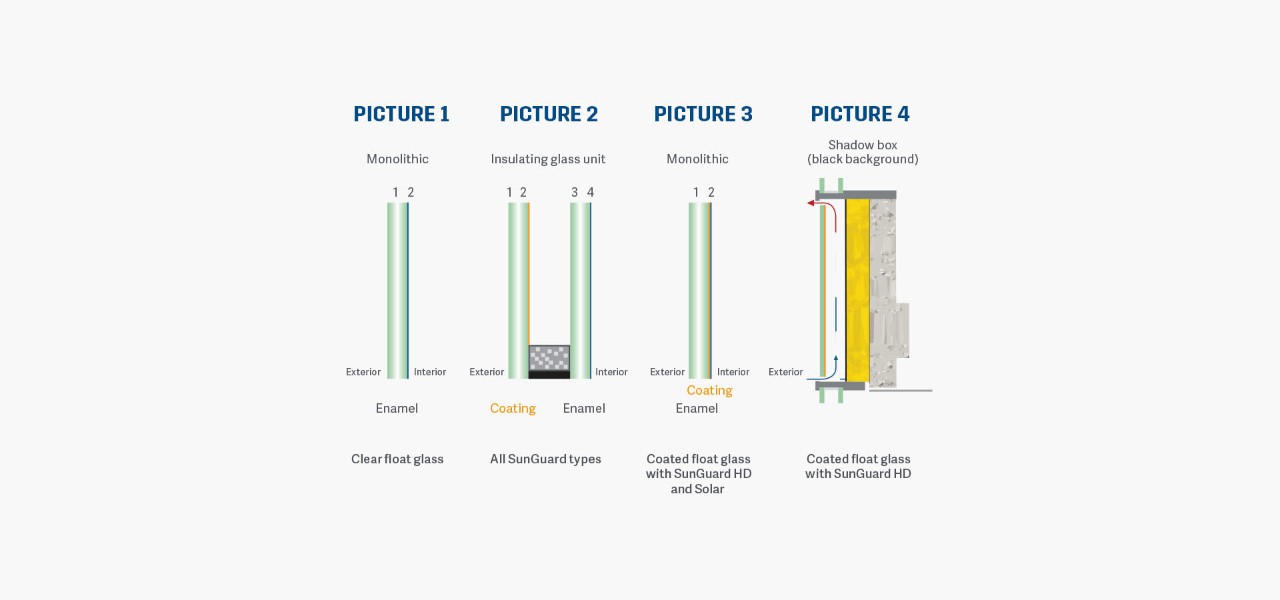

Structural Basics Words "spandrel" is an architectural term that describes an archway or various other crested system of supports. Spandrel glass is just one of the only types of glass capable of covering this kind of framework in such a way that not only fits its curvature, however also creates the impression of a single and unbroken wall.

Treatment these with glass can often develop a more pleasing, polished appearance than would certainly filling them in or constructing a more standard wall over them. This kind of glass has a tendency to be opaque, and also is usually reflective. Often people can see out of it, but most of the times it in fact fends off light as well as usually shows up to have a mirrored surface.

Aesthetic Top Qualities Among the most valued elements of this material is its ability to develop an overall consistent look. The glass is commonly tinted, and therefore it can match most various other kinds of glass that are utilized to produce a building front. Green and also blue colors have a tendency to be several of one of the most common, as these have the ability to mirror the skies with specific precision.

Various industrial structures have actually been lined with spandrel glass on the inside in addition to the outdoors in order to trap and also maintain solar heat, which can lower energy prices and promote "eco-friendly" environmental techniques. The startup costs can be high, however the cost savings over the lengthy term can be visit their website considerable.

Replacement Glazing Panels - Truths

The UK Building Laws Approved Record B (fire safety and security), Withstanding fire spread over outside walls section (Quantity 1: Section 10/ Quantity 2: Area 12), specifically states that window spandrel panels as well as infill panels need to abide with best site the needs of condition 10. 1, or provision 10.

6 and Appendix B4. secondary glazing panels. Law 7( 2) puts on notifiable structures over 18m. They should follow the demands that analyses can not be used as a kind of compliance, i. e. moving to a testing as well as certification strategy that has actually been heightened within the rainscreen industry over the last 3 years.

This is very unlikely with these sorts of systems when an adhesive is introduced right into the panel building and construction, as an adhesive can not be licensed to EN13501 as an individual layer, as well as if tested as component of a system, it is not likely to have a calofic value for the adhesive layer low sufficient to accomplish the needs of an A1 score.

It deserves keeping in mind that adhesive is not the only material that can restrict a panels qualification. Including a pay per click paint (Polyester Powder Coating) would certainly likewise cause a decrease in the rating of the system, as the finish would not be able to be licensed as a solitary layer and thus, any panel with a PPC Finish to Qualicoat 2 criteria would only achieve an A2 rating.

How Aluminium Spandrel Panel can Save You Time, Stress, and Money.

It deserves remembering it is extremely not likely that a spandrel panel can achieve A1 fire qualification to EN 13501 with these sorts of systems when a glue or PPC finish is introduced right into straight from the source the panel building. That is why it is so essential to obtain it right when defining spandrel panels.

The only way of being particular that a spandrel panel achieves the required fire ranking is to ask your vendor for evidence that they have executed screening to the appropriate requirement - insulated spandrel panel. This will give confidence that the spandrel panel being specified will be in line with the demands of the changed 2019 Structure Rules To find out more about our spandrel panels please contact us Share this post:.